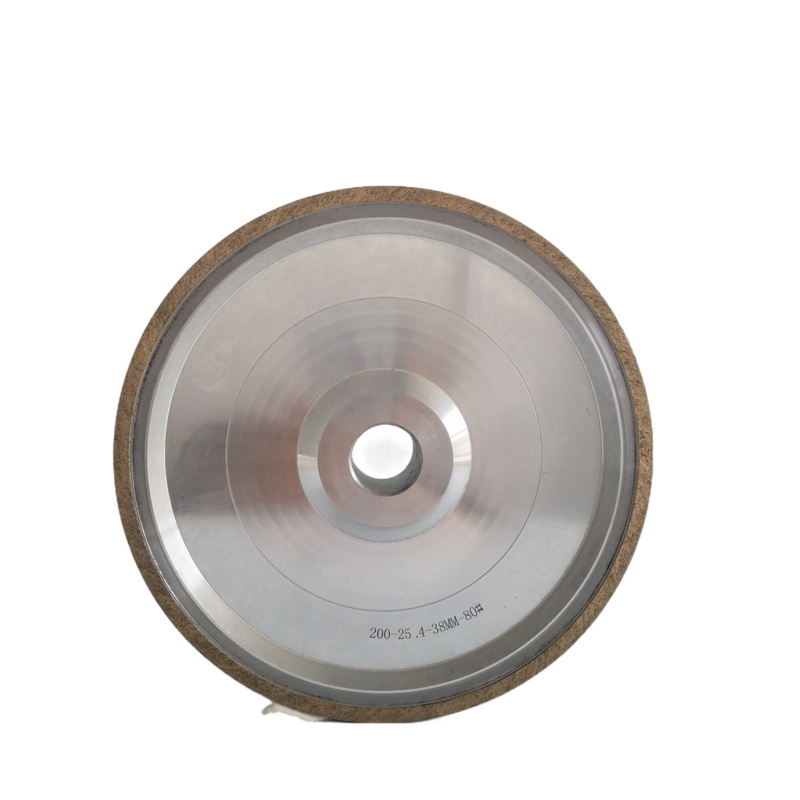

Sintered Metal Binder Diamond Grinding Wheel

1. Mekhahlelo ea lihlahisoa

| Bophara ba ka Ntle(mm) | Botenya(mm) | Bophara ba Lehlabathe(mm) | Mesopore(mm) |

| 150 | 38 | 5 | 25.4 |

| 150 | 50 | 5 | 25.4 |

| 200 | 28 | 5 | 25.4 |

| 200 | 38 | 5 | 25.4 |

| 200 | 50 | 5 | 25.4 |

Granularity: 40 #, 60 #, 80 #, 120 #, 180 #, 200 #, 280 #, 360 #, 400 #, 600 #, 800 #, 1200 #, 1500 #, 2000 #, joalo-joalo;Boholo bo ka raloa ho latela litlhoko tsa moreki.

2. Tlhahiso ea lihlahisoa tse tala

Khetha e tsoang kantle ho naha bohale bo phahameng, matla a phahameng, taemane e phahameng ea ho roala e le abrasive.

3. Thekenoloji

Metal fastener ke mofuta oa ntho e khomarelang e entsoeng ka lihlahisoa tse tiileng tse entsoeng ka tšepe kapa lerole la alloy e le ntho e kopanyang le mokhoa oa metallurgical oa phofo bakeng sa ho eketsa mebala.E le papiso, sekontiri sa boronse se sebelisa lerole la boronse e le karolo ea mantlha ea tšepe 'me se kopanya lerole la tšepe le eketsehileng joalo ka tin, nickel, iron, silver, zinki, le lead ho hlahisa ntho e khomarelang.

4. Likarolo tsa sehlahisoa

E bentšitsoeng hantle, e betliloeng ka mokhoa o rarahaneng, e nang le sebopeho se thata.E bonts'a ponahalo ea selikalikoe le e boreleli, ho tsepamisitsoe maikutlo ho babatsehang, ho sila ka boreleli, le bokhoni bo phahameng;e emelang mefuta e meng e baballang litšenyehelo ho feta lihlahisoa tse ka bapisoang le tse tsoang kantle ho naha.

5. E fapane le lihlahisoa tse tšoanang 'marakeng

Ha re se re nahanne ka seo mosebedisi a se rerileng bakeng sa ho bentsha, basebetsi ba rona ba botekgeniki ba tla khetha mofuta o loketseng ka ho fetisisa oa taemane hore o sebetse joalo ka abrasive.Nakong ea ts'ebeliso ea lisebelisoa tsa rona, bareki ba hlokometse ts'ebetso e phahameng ea ho sila, nako e telele ea bophelo, liphetho tse ntlafalitsoeng tsa ho sila, le bokhoni ba ho nka sebaka sa lihlahisoa tse ts'oanang tsa kantle ho naha ho ipapisitsoe le ts'ebetso ea tsona ea litšenyehelo.

6. Sebaka se sebelisoang

Ha ho tluoa tabeng ea ho etsoa ha liphanele tsa silicon tsa monocrystalline, re sebetsa ka ho khetheha tabeng ea ho sila safire, mekhoa ea chamfering, ho betla majoe a bonono, le ho sebetsana le likarolo tse fapaneng tsa mechine tse kang li-angles le li-grooves.Ho feta moo, re boetse re ipabola tabeng ea ho hloekisa lipeipi le ho lokisa likoti le bokaholimo bo ka hare.